Toyota Lean Management (TLM)

With increased customer demand and high competition in today’s market, it is more important than ever for businesses to hone in on developing processes to help their operations perform more efficiently, while ensuring consumer satisfaction.

Maximize Efficiency and Eliminate Waste with TLM

TLM is a model based on helping organizations identify the key ‘pain points’ in their operation and work to eliminate waste in ALL areas – not limited to manufacturing. To ensure your process increases in efficiency and productivity, you’ll need to make sure you have the proper pieces so every individual in your organization understands the expectations of going lean. This system aims to improve the bottom line by creating workspaces that are free from clutter to increase productivity, safety, efficiency, and employee satisfaction.

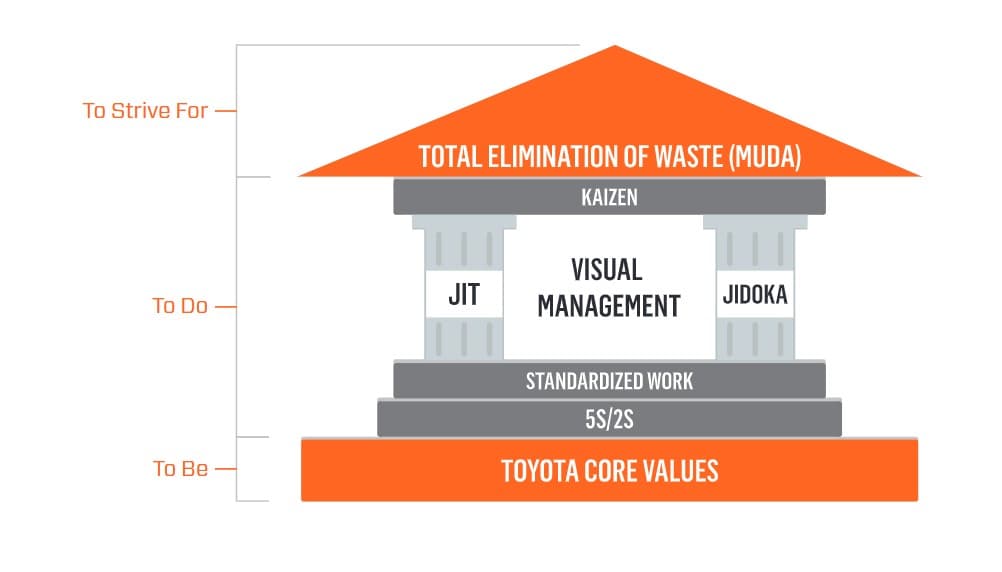

Building a Strong Foundation

Five key steps to Toyota’s Lean Manufacturing methodology

Sort

Set in Order

Shine

Standardize

Sustain

Lean Management Pillars

Just as a house can’t stand without pillars, a manufacturing process can’t become better without the structure that keeps it standing. Together, combining quality production with timely delivery allows your business to move closer to their goals.

Just-in-Time

The just-in-time (JIT) concept stresses the importance of delivering only the materials necessary in a timely manner. Employing a JIT inventory management strategy for your operation allows for waste reduction, and increased efficiency, which reduces inventory costs.

Jidoka

Jidoka, which is translated “automation with a human touch” means that once a problem occurs in the process, humans are empowered to stop production. This prevents defective products from being produced. Stalling production during these times decreases inventory costs as well as warehouse space.

Support Beams

Before finishing the roof, a house requires an additional beam to ensure the structure is sound. Kaizen, which translates to “continuous improvement,” stresses the idea that no process is perfect and challenges should be welcomed. Each day, improvements can be made to the process or product to create an operation that is more efficient than the day before. Doing so, can result in substantial cost and time savings as well as helping the organization, team members, and individuals increase their performance.

Roof (Eliminating Waste)

Completing the House of Toyota involves building the final touch, the roof, to reach its full potential. Setting clear goals for your organization is essential to avoid missing growth opportunities and achieving new heights. Eliminating excess inventory, overproduction, and defects (muda) can help reduce operational costs. Focusing on providing high-quality products to customers quickly is key to achieving a lean warehousing or logistics operation and ensuring customer satisfaction.